What type of Material is used in Orthopedic Implants?

There are 3 categories of materials currently used in prosthetic devices

1. Metals

2. Polymers

3. And ceramics

Metals

Metals used in orthopedic implants include surgical grade stainless steel (commonly 316L), cobalt-chromium (Co-Cr) alloys and pure commercial titanium (Ti) or titanium alloys.

- Stainless steel is used for non-permanent implants, such as internal fixation devices, because of its poor fatigue strength and liability to undergo plastic deformation.

- Before the use of titanium, cobalt-based alloys had largely replaced stainless steel as materials for permanent implants. These alloys are generally more corrosion resistant, owing to the formation of a durable chromium oxide surface layer. Despite the good corrosion resistance, ion release in vivo is a major concern, as chromium, nickel and cobalt are known carcinogens.

- Titanium use in orthopedic implants involves pure commercial titanium and titanium alloys, such as Ti-6Al-4V, for example. These metals have been demonstrated to be highly biocompatible. Nevertheless, some concern remains as to the effect of vanadium and aluminum. Titanium and its alloys are more corrosion resistant than Co-Cr alloys because of the formation of titanium oxide on the surface. This layer, however, may be porous and rather friable. Abrasion of this titanium oxide layer can lead to the release of particles into the surrounding tissues. Although titanium implants have been considered to be the most biocompatible, these debris particles may well cause an undesirable tissue response with eventual long-term aseptic loosening of the implant.

Polymers

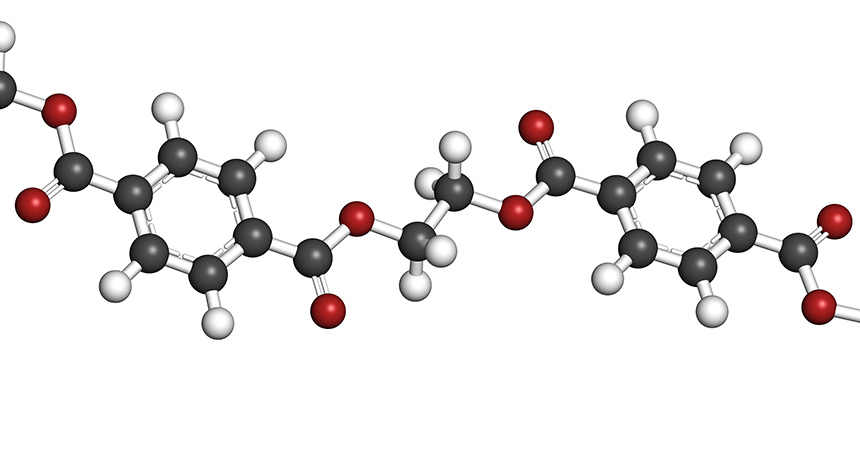

- Polymers are formed by linking a large number of monomers through chemical reactions. In organic polymers, the monomer is an organic molecule with a central carbon atom.

- The most used polymer, in orthopedics, is ultra-high molecular-weight polyethylene (UHMWP) or high-density polyethylene (HDP). Thus far polyethylene is the best material for articulating with metal or ceramic.

- One major problem in polymers is the slow, temperature-dependent, deformation it suffers under load, commonly called “creep“. Another concern with polyethylene is the progressive wear.

- Carbon fiber has been used for reinforcement of the mechanical strength of polyethylene. Although creep and tensile strength could be improved, resistance to surface wear was decreased.

- In spite of the increasing implantation of cement-less devices, the use of self-curing bone cement, which is an acrylic polymer, remains widespread. Modern cementing techniques are responsible for the much improved clinical outcome of cemented prosthetic implants. It should however be emphasized that cement does not act as a glue, but merely as a filler which allows mechanical anchoring of the implant and transfer of load from the prosthesis to the bone. Compared to cortical bone, polymethylmethacrylate (PMMA) is relatively weak with respect to nearly all mechanical properties. Its low modulus of elasticity appears to be an advantage in that it allows a gradual transfer of stress to bone.

Ceramics

- The ceramics used in orthopedic implants include aluminium oxide and calcium phosphates. These ceramic materials are very resistant to compression, but weak under tension and shear, and brittle.

- Aluminium oxide (Alumina) ceramics are formed by the simultaneous application of pressure and temperature to a powder. This process, called hot-pressing, leads to a final product with high density, small grain size and good mechanical properties.

- Ceramics have a high modulus compared to bone (330.000 MPa). This may result in fracture of bone or early loosening of ceramic acetabular sockets because of the high noncompliant elastic modulus.

- Although in vitro tests revealed excellent results as to tribology and wear for the combination of alumina-to-alumina (head and socket), unacceptable wear after some years of clinical use has been observed. Another reason for discontinuation of its use is the low resilience of this ceramic. This property may adversely influence impact crack initiation and propagation. Instead, ceramic to HDP articulating surfaces are being used.

- Calcium phosphate ceramics are particularly attractive as implant coatings because of their high biocompatibility and reactivity. Titanium and titanium alloys are coated with hydroxyapatite (HA) using several methods. These calcium phosphate implant coatings have been shown to result in strong early porous implant fixation and early bone ingrowth.

- Other ceramic materials are commonly used, such as zirconium oxide (Zirconia) and silicon oxide (Silica).

M Care being the global supplier of Pharmaceutical formulation, API, KSN & intermediate products and a member of Pharmexcil are ready to provide international exposure to manufacturers for registration of their products and sales and academia for research and development. We also assist clinical research.We are exporting medicines from India to different countries like United Arab Emirates, United States, Brazil, Saudi Arabia, etc. If you are looking for another product or brand click here.